Deciding on the Right Flute Profile for Your Packaging

When you’re designing custom corrugated boxes, you’ll have the opportunity to decide which flute profile would be best for your product. There are multiple profiles to choose from, and you’ll want to understand the uses of each before making your final decision. That’s why the experts at Jamestown Container put together this quick resource breaking down common flute sizes and their unique benefits. Read on to understand what a flute is and the different profiles available to you.

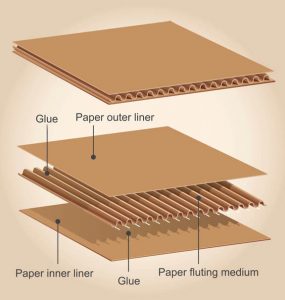

What is a Flute?

Flutes — also referred to as corrugation or corrugated medium — are the wave-like lines or arches adhered to layer(s) of linerboard. These are what give the linerboard extra strength and support to handle even the heaviest of items. Flutes provide structure to the board as well as extra layers of insulation, helping increase the crush-strength and puncture-resistance of your custom corrugated boxes.

Flutes come in different sizes or “profiles,” each having their own unique advantages, making them useful in different circumstances. Below we review the five most common flute profiles; A, B, C, E, and F, to help determine what’s right for your product.

A-Flute

This is the first type of flute ever designed and has 32-38 flutes per foot. As the thickest available flute, it provides the best cushioning and vertical compression strength for fragile products. Its stiffness and crush resistance make it a popular choice across a wide range of industries; however, the wide space between flutes makes the surface of the board less smooth and not an ideal choice for printing detailed designs.

B-Flute

At 44-52 flutes per foot, B-flute has more flutes per foot than A-flute, and also has a lower arch height, making it a much thinner board. It has a stiffer, flat surface that makes it great for die cutting and printing high-quality designs. B-flute has great puncture and crush resistance. It was originally developed for packaging canned goods and is now commonly used for beverage trays, glass-to-glass packs, and more. This profile is also a common choice for inner packaging like pads or dividers.

C-Flute

As the second-thickest corrugated flute available, C-flute has 36-41 flutes per foot and was developed as an all-purpose flute. It has optimal crush resistance, stacking strength, and printing properties, making it the most commonly used flute size for shipping boxes. It’s great for transporting glass products, dairy, furniture, and much more.

E-Flute

E-flute is much thinner than the other profiles and has 74-98 flutes per foot. Although slim, it has great crush resistance, is easy to fold, and offers a smooth surface that lends itself perfectly to high-quality print. These characteristics have contributed to E-flute becoming a stronger, more environmentally friendly alternative to folding cartons in the retail packaging of consumer goods. However, E-flute is not an ideal shipping container due to its subpar performance in puncture protection.

F-Flute

Referred to as a “micro-flute,” F-flute is half the thickness of E-flute and has 124-128 flutes per foot. With less fiber in the material, F-flute is very rigid and is another common alternative to folding cartons. Due to its similarities, it is sometimes interchangeable with E-flute. It’s most commonly used for specialty packaging, small retail packaging, and clamshell packaging in the US fast-food industry.